3D Printing is a group of technology contained within the umbrella of Additive Manufacturing. The term Additive Manufacturing includes technologies such as Rapid Prototyping, Direct Digital Manufacturing and of course 3D Printing.

Essentially, 3D printing is the process of making three dimensional solid objects from a digital model. 3D printing is achieved using additive processes, where an object is created by laying down successive layers of material. Popular makes of 3D printers includes such names as Prusa, Ultimaker, Formlabs, etc.

Not all 3D printers use the same technology. There are several ways to print and all of them uses additive manufacturing. However, different printers differ mainly in the way layers are built to create the finished model.

Rapid prototyping methods includes the following types of technologies:

- Fused Deposition Modeling (FDM) – For this method, filaments of heated materials are extruded from a horizontal moving tip.

- Stereolithography (SLA) – This method forms physical models from liquid photosensitive polymers that gets solidified through being exposed to ultraviolet light.

- Laminated Object Manufacturing (LOM) – For this method, layers of adhesive-coated sheet material are sticked together to form the physical model.

- 3D Ink Jet Printing – This method employs ink-jet technology to build the model.

As of this writing, current 3D printers uses G-code.

The standard digital file format for 3D Printing is STL. ‘STL’ stands for Surface Tesselation Language or ‘STereoLithography file’. A STL file is a triangular representation of a 3D object. There are 2 favours of STL,

ASCII and Binary. The ASCII STL files can become very large. The binary version is usually smaller.

The Generic Workflow for 3D Printing

More often than not, in order to get from start to a fully realised 3D printed model, 3 components or aspects are required:

1. 3D Modelling Program (Software)

The program used to create the model which will later be exported as an STL file.

2. Slicer or 3D Printer Host (Software)

A Slicer or slicing program takes in the STL files and convert the 3D model into printing instructions for your 3D printer. It cuts the model into horizontal slices (layers) and generates toolpaths to fill them.

3. 3D Printer (Hardware)

The hardware that translate the 3D data into physical object. There are many makes of 3D printers on the market, sport various types of technologies.

3D Modelling for 3D Printing

At Studiorola, we offer 3D modelling training (in Singapore and Asia) pertaining to 3D printing and rapid prototyping in general.

>>> Click here for information on 3D Modelling for Printing Training.

The training is conducted using the powerful and yet free opensource software Blender. That means, the Participants do not need to spend additional money for buying any costly 3D modelling program. Blender can create highly detailed 3D models that are suitable for 3D fabrication (if the proper understanding and techniques are exercised! )

Below is a screen capture of an organic model created in Blender and being evaluated for 3D printing feasibility.

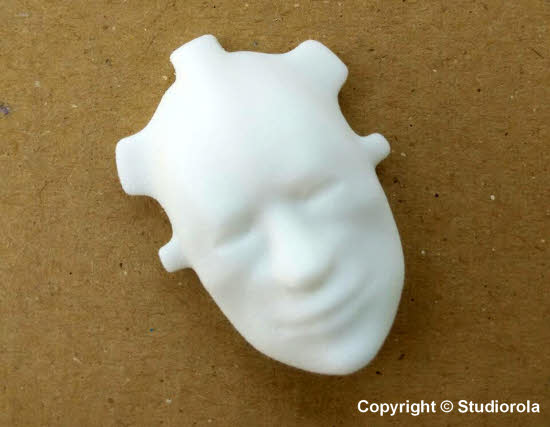

Below shows the above Blender 3D model being printed as a physical plastic model.